How To Repair A Tube & Shell Oil Cooler

This commodity will discuss removal and installation of tubeless tires.

i

Preliminary Info

What Tools practice I demand?

- Tire levers

- Air compressor and inflator caput

- Tire sealant and measuring cup

- Rags to remove onetime sealant

- Soapy water to lubricate tight beads

- Valve cadre remover

- Syringe such equally TSI-1

Get-go, verify that your components are tubeless uniform. See Tubeless Tire Compatibility for more than information on tubeless tire standards.

3

Tire Installation

- Check that the valve is secure in the rim.

- Check for any arrows printed on the sidewalls that point management of wheel rotation. Marshal the tire with the rim appropriately. It can besides be useful to place the recommended tire pressure label on the tire adjacent to the valve stem.

- Install one bead on the rim.

- Install the second bead kickoff at the valve. Leave a portion of the bead uninstalled.

- Add together sealant.

There are two principal methods for calculation sealant to the tire:

Method ane — Cascade Method

This method requires a measuring cup. An air compressor is highly recommended.

- Check the characterization for the recommended amount of tire sealant and pour in the sealant.

- Slowly rotate the bike to keep the fluid at the lesser while your unmounted bead comes to the top. Finish installing the dewdrop.

- If it's a tight bead, it can help to use soapy water and lubricate the dewdrop. Employ a tire lever when necessary.

- Inflate the tire to at to the lowest degree the maximum pressure on the label. If the tire bead and rim are well designed and compatible, this tin also work with a flooring pump.

Method 2 — Injection Method

This method requires a valve with a removable valve core, a syringe, and an air compressor.

- Check the label for the recommended amount of tire sealant and fill the syringe.

- Mountain both tire chaplet to the rim before calculation any sealant.

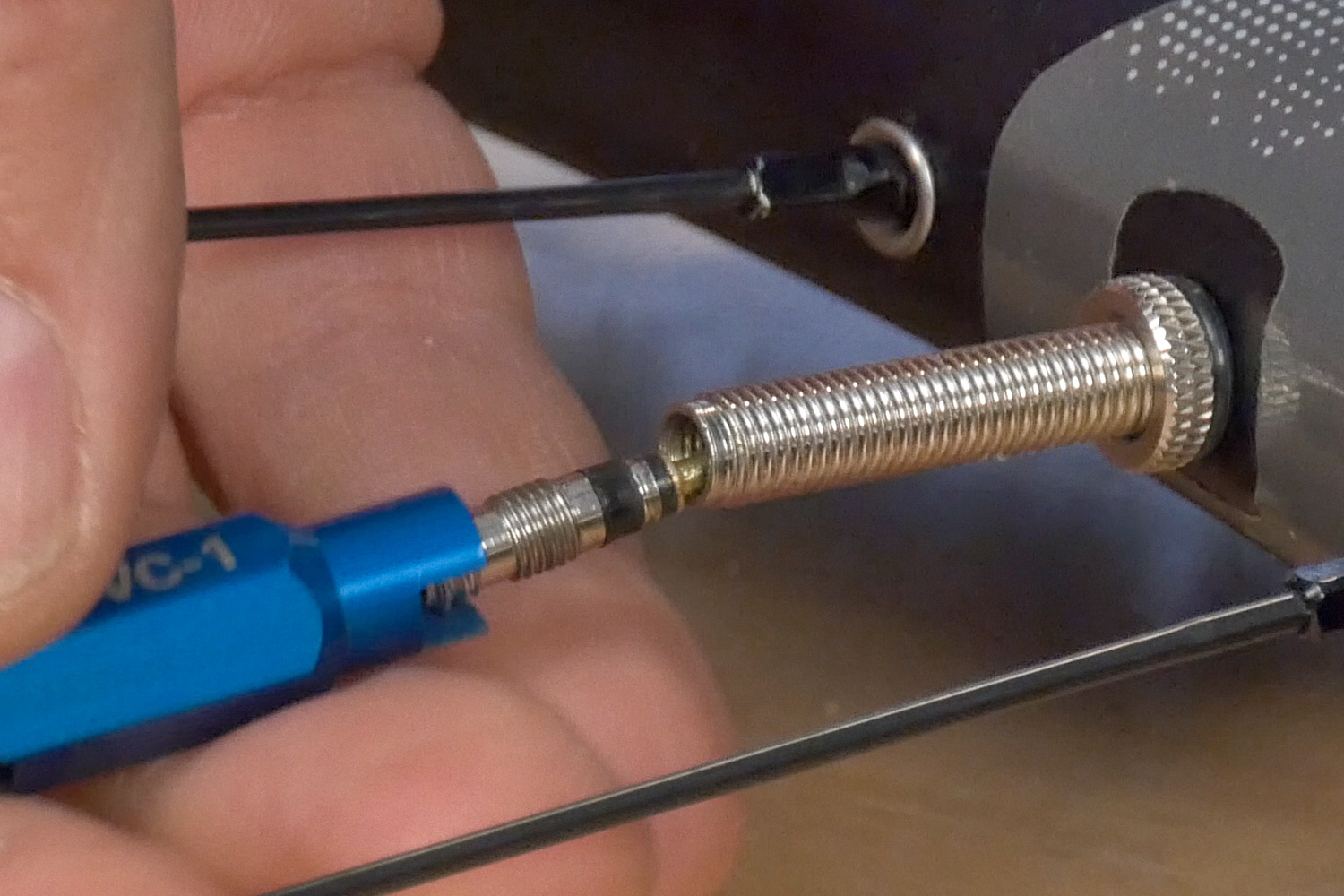

- Verify that the valve is secure in the rim, and then remove the core using a valve core remover such as the Park Tool VC-1.

- Inflate the tire fully with an air compressor, allowing the bead to fully seat. If the tire bead and rim are well designed and compatible such as the UST organisation, this tin can as well piece of work with a floor pump.

- Pull off the air caput. For the most part, the dewdrop volition still stay seated to the rim.

- Inject the fluid.

- Install the valve cadre and secure.

- Check that the tire dewdrop is correctly seated. In some cases, the dewdrop will be too depression. Deflate the tire, break the dewdrop at the low point, and lubricate with soapy h2o. Reinflate.

- Spin the wheel to motion sealant effectually within the tire.

- Hold the wheel horizontally and oscillate the bike to help spread the fluid to the dewdrop. Flip the cycle and repeat.

- Now nosotros wait. The sealant needs to fully set and block any leaks. On UST systems, this may happen immediately. For other systems, it may take hours, and in some cases, days. This is considering the sealant has to find and plug the leaks.

Sealant seeping through the tire bead

The rim strip on this cycle was not adequately sealed. Sealant may, in time, create a seal

- Every few hours, maintain air force per unit area and spin the wheel to spread the sealant.

- When the wheel is holding air consistently, prepare the tire to the rider'southward desired pressure. This wheel is fix to use.

4

Tubeless Tire Repair

In general, punctures in tubeless tires cannot be repaired. Punctures in UST tubeless tires, and other tubeless tires with a butyl inner lining, tin can potentially be repaired using a vulcanizing patch kit such as the VP-1. Information technology is not recommended that y'all attempt to utilize other types of patches, or effort to repair other types of tubeless tires.

Encounter Inner Tube Repair for instructions on using a vulcanizing patch kit.

How To Repair A Tube & Shell Oil Cooler,

Source: https://www.parktool.com/blog/repair-help/tubeless-tire-mounting-and-repair

Posted by: smithobby1983.blogspot.com

0 Response to "How To Repair A Tube & Shell Oil Cooler"

Post a Comment